Want to achieve the highest quality in precast parts and at the same time reduce production costs?

At MTT-MAXIM we will show you how to achieve this with the PAUL range of prestressing machinery and consumables.

PAUL IS THE WORLD LEADER IN PRESTRESSING

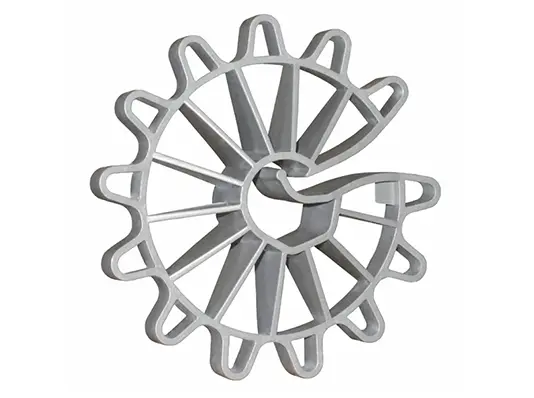

Function of PAUL prestressing equipment

PAUL prestressing equipment is used to apply the necessary tension to the cable, forming the required active reinforcement in precast elements.

For which applications is it required? It is indispensable for the manufacture of any prestressed item, from small beams to roof trusses or bridge girders.

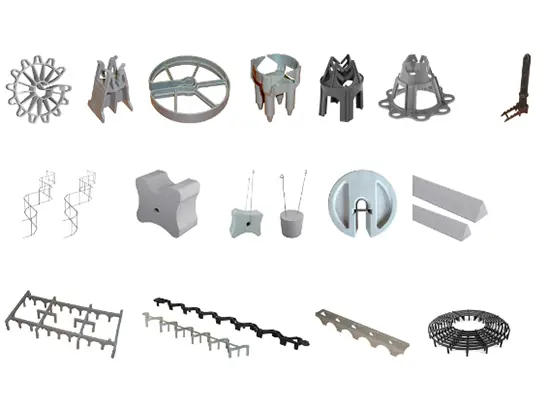

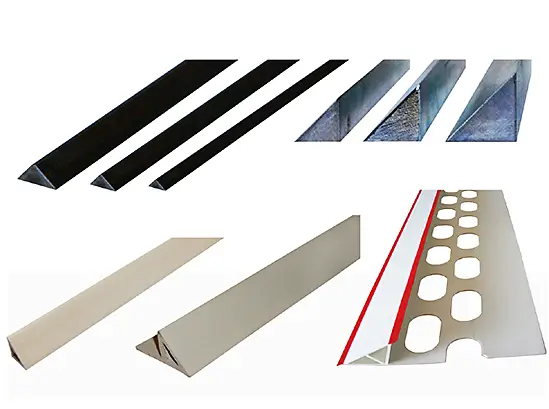

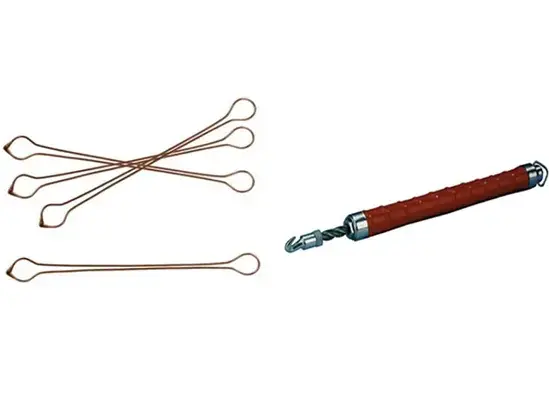

4 PAUL product families you should know about

Exclusive advantages of the PAUL prestressing system

All cylinders, including the steel gripping cylinder and the support head for anchor nailing, are HYDRAULICALLY actuated.

Moreover, there is a leap in quality as far as the clamps are concerned:

- One and the same clamp is suitable for tensioning different diameters of stranded wire/cable.

- The gripping range is much greater.

- The service life of the consumables (clamps) is increased, thus reducing replacement costs and time wastage.

- Guarantees absolute reliability without slippage, extending the life of the wedges.

If you want to reduce production times and costs while increasing safety, you should choose PAUL prestressing machinery and consumables. The latest technology in the industry is reflected in higher quality and more efficient products with an unrivalled service life.

For further information on prestressing machinery or consumables, please contact us for a full guide with no obligation.