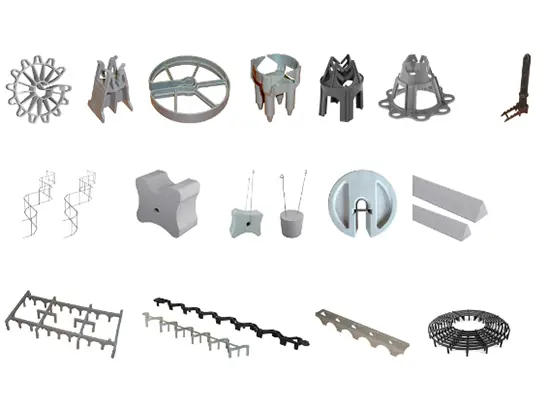

We supply all kinds of formwork accessories

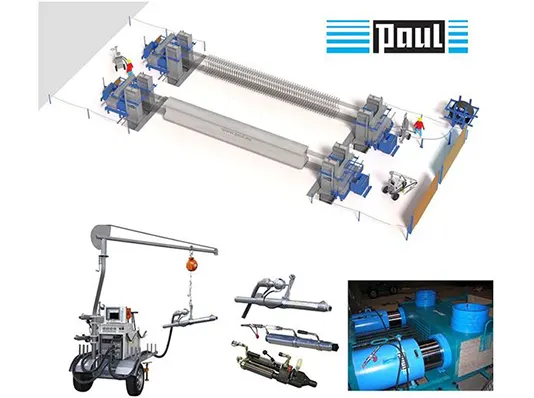

In the precast concrete sector formworks are systems of moulds or slabs designed to support freshly poured concrete until it hardens. Typically, formworks are temporary structures, but some of the elements used in the process are absorbed and remain integral parts of the construction.

Formworks allow the concrete to be shaped before it sets, and are primarily used for foundations, walls and columns.

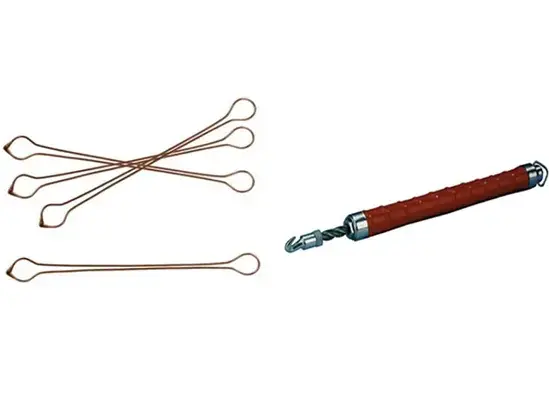

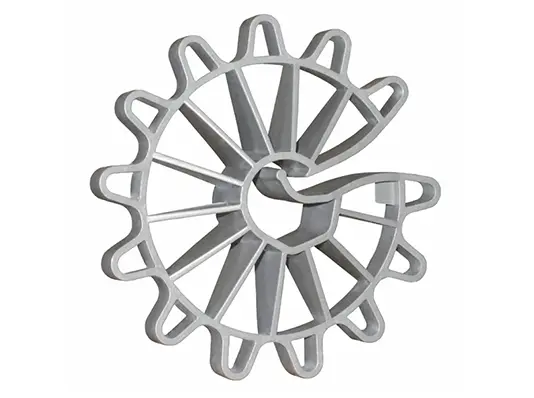

Accessories for formworks include the bars or spacers used to connect and secure the formworks, also known as Dywidag formwork rods.

Characteristics of formwork rods and other accessories

Dywidag system formwork rods or bars always provide a high level of security and reliability to the concrete structure. These systems are equipped with various anti-corrosion methods that significantly extend their service life on any construction project. The selection of the best materials and components ensures high-performance work.

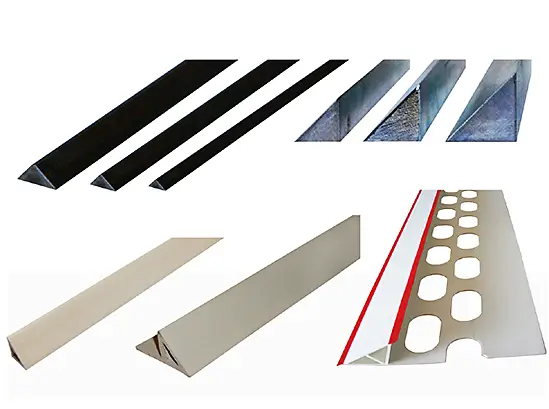

In addition to these bars or spacers, within the formwork we required other elements that guarantee watertightness to prevent concrete leaks or surface defects. To ensure this, a series of formwork accessories are used, such as tubo-fix, corrugated pipes, cones, and others.

Advantages of our formwork accessories

3 recommendations when using formwork rods and other accessories

- To guarantee a good finish on the concrete structure, we must ensure that the materials we use for each job are clean and in good condition. If, on the contrary, these accessories have remnants of concrete from their previous use, they can leave marks on the new structure.

- To prevent concrete from sticking to metal formworks, the general practice involves applying form release oil to the inner surface. This chemical product acts as a release agent, facilitating the removal of temporary formwork elements by preventing adhesion. Before carrying out this phase, we must ensure that the concrete has fully set and not remove the moulds too soon.

- Finally, once the temporary structures have been removed, whether they are moulds or formwork panels, the entire surface must be cleaned for the next job. Metal accessories only need clearing with pressurized water and nothing else. On the other hand, in the case of wooden accessories, we should apply oils after cleaning to keep them in good condition for as long as possible.